Using The VSM Data Box Form

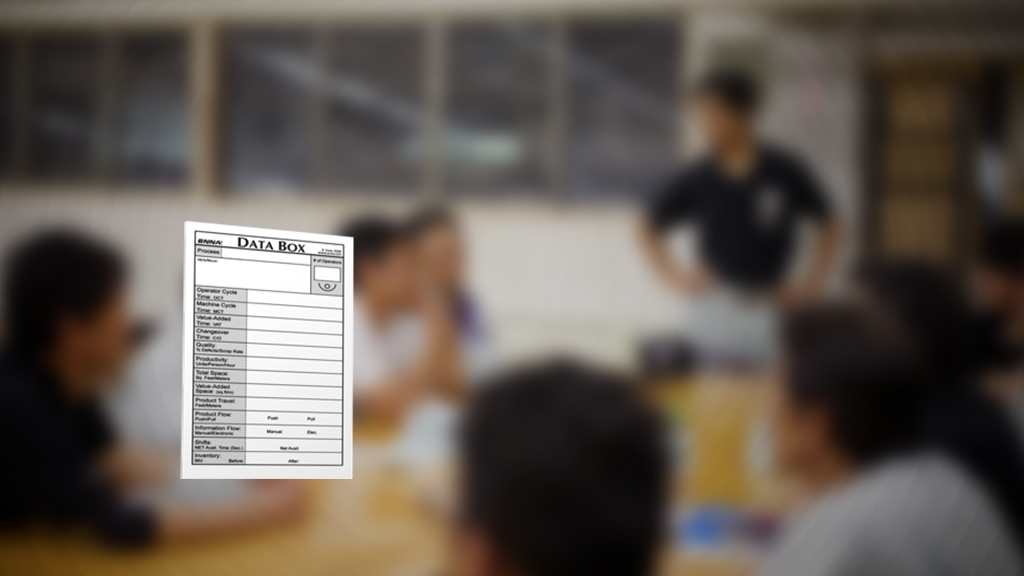

Data Box

Topic

Value Stream Mapping (VSM)

Summary

The Data Boxes have the typical measurements that most companies use when undertaking process improvement measures to develop your unique value stream process.

Objectives

Data Boxes standardize information gathering and keep the user focused on accurate collection.

Summary of Steps

- At the top, mark name of the process, the number of operators, and a sketch of the action or thing concerned

- Operator cycle time (OCT)

- Actual operator hands on time

- Machine cycle time (MCT)

- Machine process time not including changeover

- Value-added time (VAT)

- Time that the part or product is actually changing form

- Changeover time (C/O)

- Time from the last good part of the previous run to first good part of the new run

- Quality

- Percentage of defects including scrap

- Productivity

- Products per person per hour

- Total space

- Total foot print of the area including storage, machine, and work areas in square feet

- Value-added space

- Actual space where value-added activity occurs; usually about six inches greater than the actual product

- Product travel

- Total linear feet traveled by the product

- Product flow

- Push or pull?

- Information flow

- Physical hardcopies or electronic information?

- Shifts

- Number of shifts used in the process

- Used to determine available time:

- Total time of a shift minus break and lunches

- Used to determine available time:

- Number of shifts used in the process

- Inventory

- Current measurement of inventory before and after the process

- For inventory between processes, count the inventory before the process so the inventory will not be double counted

- Current measurement of inventory before and after the process

Included in:

VSM Training Package

VSM Office Workflow Training Package

Additional Resources

Lean Dictionary