Using The Autonomous Maintenance Form

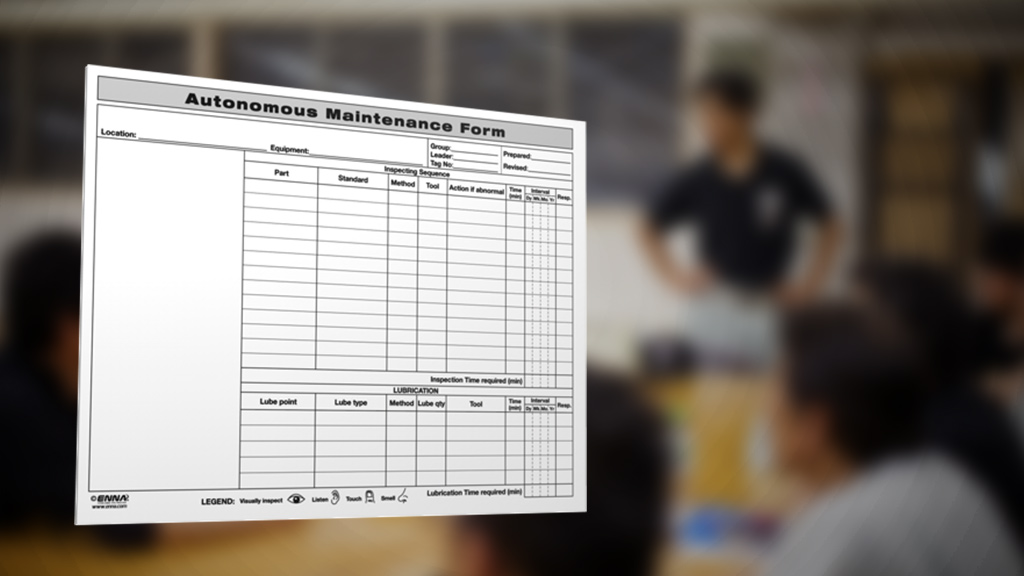

Autonomous Maintenance Form

Topic

Total Productive Maintenance (TPM)

Summary

Provides the information necessary to systemize the maintenance requirements of a machine or part of a machine so that the operators can autonomously maintain specific elements of a maintenance without needing other department support.

Objective

The objective of this use of our Autonomous Maintenance form is to provide you with a sample of all the elements working together to help show you the power of this form towards a more productive work area.

Summary of Steps

- Fill in essential fields at the top

- Location

- Equipment

- Group

- Leader

- Tag No

- If not relating to a TPM Tag or suggestion, leave blank, otherwise use related Tag Number.

- Date prepared

- Date revised

- For supervisor use only – and only with the help of the preventative maintenance team

- Left area

- Draw schematic with indicators that relate what will be written on the form itself

- Label and highlight specific areas of the machine that require attention

- Example: IMAGE

- Inspecting sequence

- Parts to check

- Relate back to your schematic drawing for locations

- Standard to check against (normal condition)

- Method to perform check (reference the Legend at the bottom of the form)

- Tooling to use (if needed)

- Action to take if abnormality is detected

- How long the action should take

- Interval of checks (How many times per day/week/month/year)

- Responsibility

- Total inspection time required (added at bottom of table)

- Parts to check

- Lubrication

- Lube point

- Lube type – be specific

- Greases, Engine oils, Hydraulic oils, Gear oils, etc.

- Method to perform check (reference the legend at the bottom of the form)

- Lube quantity or amount

- Tooling to use (if needed)

- Time it takes to apply lubricant

- Interval of lubrication (How many times per day/week/month/year)

- Responsibility

- Total lubrication time required (added at bottom of table)

- Legend (use these in the “method” category in both tables)

- Visually inspect (eyeball)

- Listen (ear)

- Touch (finger)

- Smell (nose)

Included in:

TPM Training Package

Additional Resources

Lean Dictionary