Using The 7 Wastes Observation Form

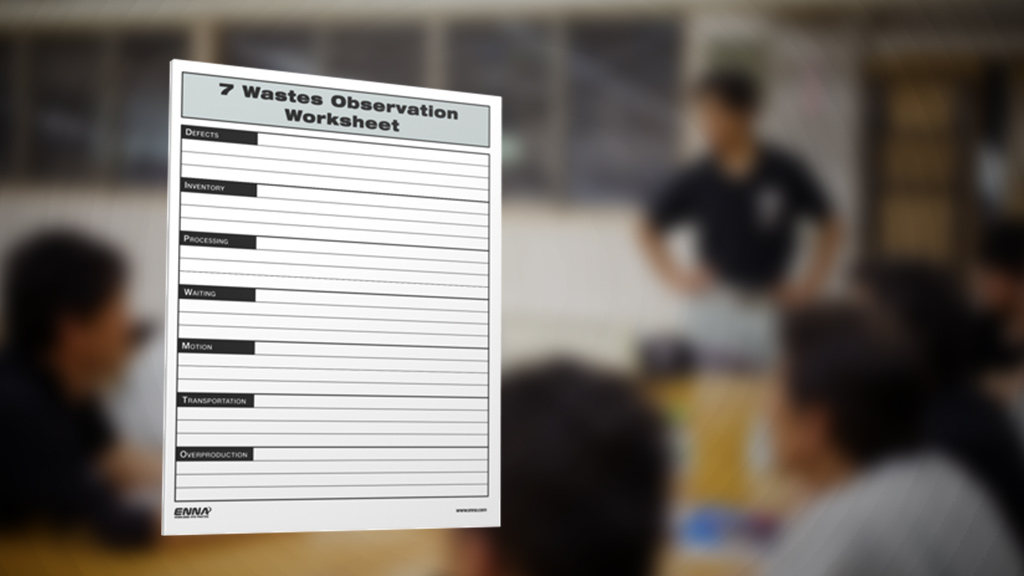

7 Wastes Observation Form

Topic

7 Wastes, Overview of Lean, Lean Manufacturing, SMED Quick Changeover, Classic Kaizen

Summary

A Tool to be used to document, present, and analyze opportunities to eliminate waste in an area or department. This form is normally used during a workshop or a manager’s gemba walk.

Objectives

Observe, document, and classify wastes into specific categories that are present on your shopfloor, in your office, or in a process.

Summary of Steps

- Go to the office, process, or gemba (the place the work is done) that you want to document

- Observe wastes and document into the correct categories or classifications of any wasteful activities identified

- Below is the definition for each classification of Waste:

- Defects

- Making bad parts, having scrap, wrong information, and/or having to rework items

- Inventory

- Any material in an area other than what is immediately needed for the next process/stage/step

- Processing

- Activity that adds no value to the product or service from the viewpoint of the internal / external customer

- Waiting

- Is created when material, information, machines, or approvals are not ready for us

- Motion

- Any movement related to people that does not add value to the product or service

- Transportation

- Moving material from one area to another area in the company

- Overproduction

- Making more products than the next process (or internal/external customer) requires

- Defects

- Below is the definition for each classification of Waste:

Included in:

Introduction to Lean Training Package

Lean MFG Workshop Training Package

SMED Quick Changeover Training Package

Classic Kaizen Workshop Package

Additional Resources

Lean Dictionary