$365.00

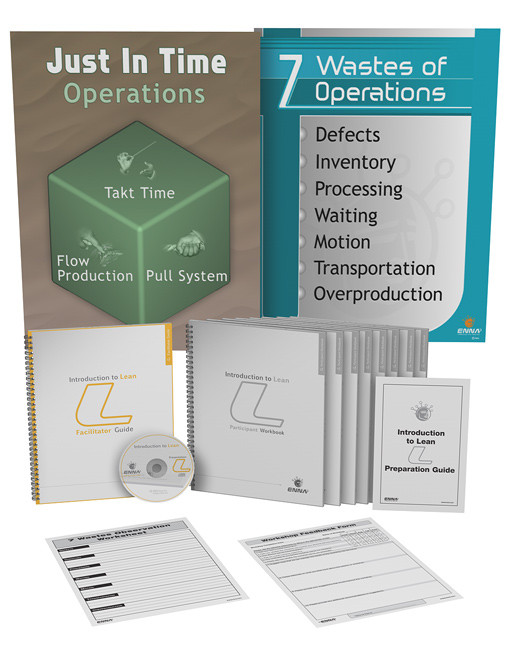

Introduction to Lean: Training Package

$365.00

The Introduction to Lean Training Package has been designed to both train staff in the principles of Lean and create the understanding needed to commit to an organization-wide Lean Transformation. This comprehensive training package is action oriented to ensure successful learning and communication of Lean Manufacturing Principles.

Overview Video “Introduction to Lean”

Features

|

Be a Leader of Change Feel confident as a Lean coach, no matter what stage your Lean education is at, with the Introduction to Lean Facilitator Guide. Providing an abundance of annotated notes, suggestions for presentation, tips for facilitating, and even a section that can be read verbatim to the participants, you never have to worry again. Whether you are a team lead or a seasoned trainer, this solution package makes training easy to accomplish. |

|

Build a Common Language In order to learn a new language you must learn the basic meaning behind each word. The same holds true for Lean. To create a culture that continuously practices Lean you must all speak a common language and hold the same understanding for what that language means. Introduction to Lean provides you with the platform to train your entire organization in this new language. |

|

Don’t Just Learn the 7 Wastes, Identify Them on Your Shop Floor People learn best when they engage multiple senses; help your employees learn the 7 Wastes of Lean by seeking out and identifying wastes on your own shop floor. After the classroom learning, invigorate the senses by getting out of your chair and walking through a common work area. By working together to identify wastes you build teamwork, encourage observation, pinpoint productivity gains, and begin to build the foundation for a continuous improvement program. |

|

Build an Understanding of Just-In-Time You can’t expect to build a sturdy house without a solid foundation – don’t expect anything less of your Lean education. This Introduction to Lean training examines the foundation for Just-In-Time: Takt Time, One-Piece Flow, and Pull Systems. Though these concepts may be counterintuitive, through explanation participants will learn to see the value in Just-In-Time. |

|

Team Building with the Flow Simulation Build confidence, understanding, and retention of concepts using the Introduction to Lean’s included Flow Simulation. The Flow Simulation provides hands-on, interactive learning to stimulate new thoughts and ideas while taking participants from a traditional batch production to One-Piece Flow. |

|

Train Multiple Teams Simultaneously Expedite your training without losing focus or quality. The Introduction to Lean Solution Package gives you the ability to train multiple teams in an engaging way, with up to 16 people at a time participating in the Flow exercise. This ensures each participant will have a pivotal role to play during the Flow Simulation exercise. |

You’ve read a few books, taken some classes, and you know what the Lean principles are but where do you start? Learn how to put your knowledge into practice using Enna’s Training Packages.

Create Your Internal Experts

Train your workforce to be active and engaging Lean Experts who take ownership of their workplace and drive lasting sustainable change throughout the organization. These people have creative time and cost saving ideas; if only they were given the support to implement them. We have designed our materials for these up and coming experts; providing the supportive materials for both the first time facilitator and seasoned trainer.

Components of our Training Packages

Facilitator Guide – Provides the facilitator with notes on presenting to the participants, background information to read before presenting that explains each slide and all the information presented, and holds the answer key to the assessment at the end of the training.

Participant Workbook – It is important for each participant to have their own workbook, as it provides each slide in the presentation with ample room for taking notes.

Preparation Guide – This accompanies each Training Package and outlines necessary materials, a timetable for each day including breaks and an approximation of how long each section should take to present and discuss, and provides a general list of activities and items that should be prepared for the workshop.

Forms – During the workshop phase of our Training Packages we provide the necessary forms to analyze and assess your operations.

Posters – The posters provided with each Training Package are a high impact, visual reminder of the concepts and tools covered during training. Use them in the training room and around the work area to reinforce the tools, methods, and concepts learned.

Tags – Are used to identify and select items of importance and vary depending on the subject matter and training package. These are used during the workshop portion of training.

Contents

* Introduction to Lean Facilitator Guide (1)

A comprehensive, easy to use facilitator guide for training employees in the principles of Lean Manufacturing and topics surrounding implementation.

* Introduction to Lean Preparation Guide (1)

The guide contains a systematic approach to preparing and executing successful Introduction to Lean workshops and is included with the purchase of a solution package. It helps the Facilitator (trainer) prepare for the event, is a reference manual for timing, scheduling, and the overall process of the workshop.

* Introduction to Lean Facilitator Digital Media CD (1)

The Digital Media CD is the focal point for training as it links the facilitator guide with the participant workbook by displaying in sequence the presentation information for the workshop. Designed using Flash technology, the presentation is a cut above anything designed in PowerPoint. It is the latest technology in presentation format, using dynamic formatting, user functionality and projection of image and content.

* Introduction to Lean Flow Simulation Application (1)

The Flow Simulation simulates the progression from traditional batch production to One-Piece Flow and the benefits realized by doing this. The exercise is centered on the use of Enna’s Flow Program. This interactive program works along with the simulation exercise to display the results of each round in a clear, easy to understand, visual manner.

* Introduction to Lean Participant Workbook (8)

Designed with the participants in mind, this workbook is used during the Introduction to Lean workshop and retained for reference. The workbook combines information, illustrations, key questions and space for note-taking. It includes a self-assessment form for participants to test their understanding of principles communicated during the workshop.

* 7 Wastes Observation Form (1)

An 8½ x 11 pad of forms used during the waste observation exercise portion of the workshop.

* Just In Time Poster (2)

A full color visual aid used during training and posted in work areas as a reference to the Just In Time (JIT) principles.

* 7 Wastes of Operations Poster (2)

A full color visual aid to be used during training and posted in work areas to remind staff to continuously eliminate waste.

Outline

1. Overview of Lean Manufacturing

- Review the History of Lean

- Learn Lean Methodology

- Study the Components of Lean

2. Understanding the 7 Wastes

- Lean Manufacturing and the 7 Wastes of Operations

- Understanding the 7 Wastes

3. Simulation and Exercise

- A guide to Flow Simulation

- The 7 Wastes Observation

Be the first to review “Introduction to Lean: Training Package”

You must be logged in to post a comment.

Reviews

There are no reviews yet.

Add Review